Printing on Unconventional Surfaces: Beyond Paper and Fabric

In the dynamic world of design and printing, creativity knows no bounds. While paper and fabric have traditionally been the primary canvases for human expression, today’s designers and innovators are pushing the boundaries of what can be printed on. From the industrial allure of metals to the natural beauty of wood, from the transparency of glass to the solidity of concrete, the possibilities are virtually limitless. In this exploration, we’ll delve into the captivating realm of printing on unconventional surfaces, where technology, creativity, and craftsmanship converge to redefine design and communication.

Unconventional Surfaces: A Creative Playground

Paper has served as a canvas for human expression for centuries. However, designers and printers have expanded their horizons to explore unconventional surfaces. Here are some exciting possibilities:

1. Metal

Printing on metal surfaces has gained popularity in various industries, including automotive, signage, and home décor. Metals like aluminum, stainless steel, and brass offer a sleek and modern aesthetic. Techniques such as UV printing and sublimation achieve vibrant and long-lasting results.

2. Glass

Printing on glass opens up possibilities for interior designers, architects, and artists. Glass panels, windows, and decorative pieces can be transformed with intricate patterns, images, and text. UV printing and screen printing are commonly used methods for glass surfaces.

3. Wood

Wood is a timeless material that blends natural warmth with design versatility. It’s often used for custom furniture, flooring, and wall art. Direct printing and transfer methods allow intricate designs on various wood surfaces.

4. Plastic

From acrylic to PVC, plastics are used for signage, retail displays, and promotional items. Printing on plastic involves techniques like UV printing, solvent printing, and thermal transfer for vibrant colors and durability.

5. Stone

Printing on stone surfaces has gained traction in architecture and interior design. Natural stones like marble and granite can be customized with intricate patterns and images. UV-curable inkjet printing achieves precise, high-resolution results.

6. Ceramics

Ceramic surfaces, such as tiles and pottery, offer a blank canvas for designers. These surfaces can be adorned with decorative patterns, illustrations, and even photographic reproductions using methods like digital ceramic printing and screen printing.

7. Leather

Leather is a classic material for fashion, accessories, and upholstery. Printing on leather allows for unique customization of bags, shoes, and even furniture. Techniques like heat transfer and inkjet printing are used for leather surfaces.

8. Fabrics Other Than Textiles

Designers experiment with unconventional fabrics like canvas and burlap for rustic and artistic pieces. These materials can be used for wall art, home décor, and more.

9. Concrete

Concrete printing revolutionizes construction and architecture. It enables intricate designs and textures on concrete surfaces, including walls, floors, and countertops. Advanced 3D printing technology is often employed for this purpose.

10. Plaster

Plaster printing is an emerging trend in interior design. Decorative plaster surfaces can be customized with intricate patterns and designs, adding elegance to walls and ceilings.

The Technology Behind Printing on Unconventional Surfaces

Printing on unconventional surfaces requires specialized equipment and techniques for quality and durability:

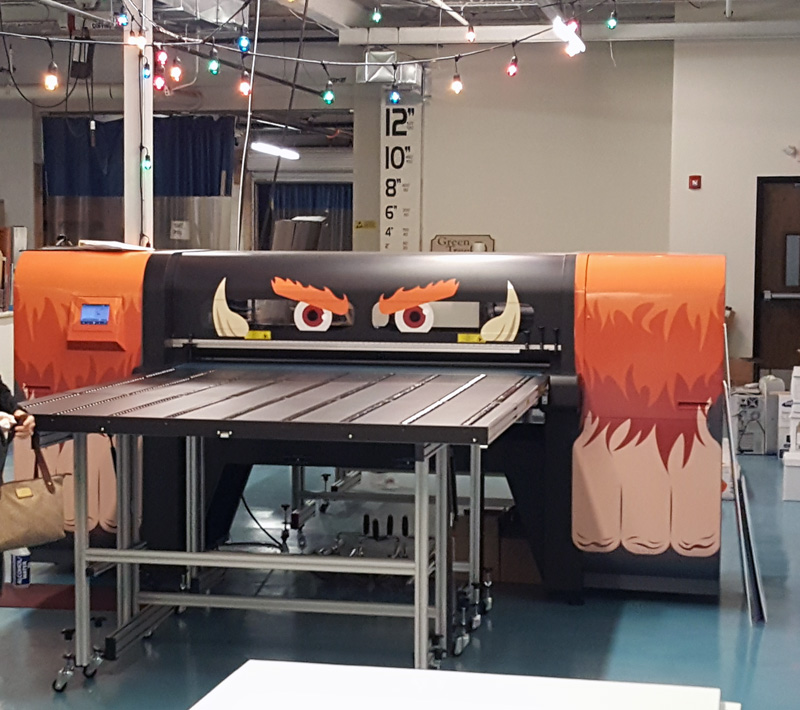

1. UV Printing

UV printing is versatile, involving UV-curable inks cured by UV light for vibrant, durable prints on metal, glass, plastics, and more. This technology ensures that the ink adheres firmly to the surface, resisting fading and wear over time.

2. Sublimation Printing

Sublimation transfers ink onto surfaces using heat and special inks, ideal for ceramics and fabrics. When exposed to heat, the sublimation inks turn into a gas, penetrate the surface, and solidify, creating a long-lasting and vibrant image.

3. Screen Printing

Screen printing transfers ink through a mesh screen onto materials, known for durability and vibrant colors. It’s a versatile technique that can be applied to various surfaces, including plastics, fabrics, and wood.

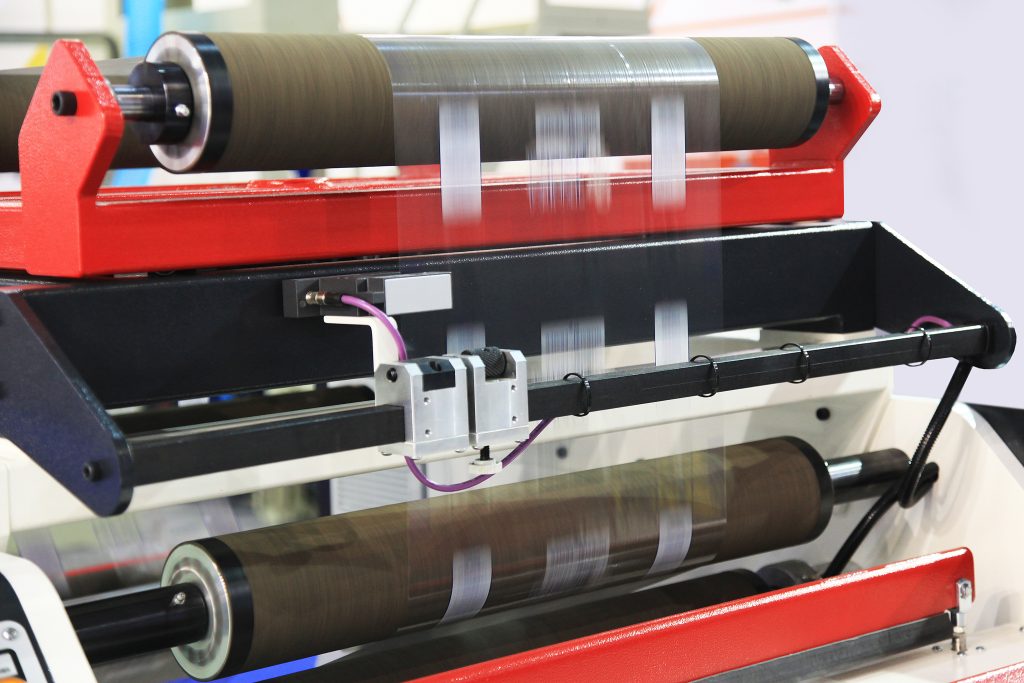

4. Thermal Transfer Printing

Thermal transfer printing involves the use of heat to transfer an image or design onto a surface, making it efficient and producing high-quality, long-lasting results. It’s commonly used for materials like leather and select plastics.

5. Direct Printing

Direct printing applies ink directly to the surface of the material without the need for transfer methods. It’s often used for wood, stone, and other porous or non-porous surfaces. Direct printing technologies include inkjet and UV-curable inkjet printing.

6. 3D Printing

In recent years, 3D printing has revolutionized the ability to print on unconventional surfaces. It allows for intricate and customizable designs on materials like concrete and plaster, enabling architects and designers to push the boundaries of what’s possible in construction and interior design. This technology has ushered in an era of architectural innovation, where buildings can be designed with unprecedented levels of complexity and creativity.

Applications of Printing on Unconventional Surfaces

The ability to print on unconventional surfaces has opened up a world of creative possibilities across various industries:

1. Architectural Design: Shaping the Future of Buildings

In architecture, printing on materials like glass, concrete, and stone has enabled the creation of unique facades, interior surfaces, and decorative elements. These printed surfaces can enhance both the aesthetics and functionality of buildings, redefining the possibilities of architectural design.

2. Interior Design: Creating Unique and Captivating Spaces

Interior designers have embraced printed surfaces as a means of transforming spaces into unique and captivating environments. From customized wallpaper to printed tiles and decorative plaster, the possibilities are boundless.

3. Retail and Branding: Making a Lasting Impression

Retailers understand the power of first impressions, and unconventional surface printing helps them create memorable and impactful displays, signage, and promotional materials. These printed surfaces play a crucial role in branding and marketing, leaving a lasting impression on customers.

4. Art and Decor: Artistry Beyond Canvas

Artists and artisans have embraced unconventional surface printing as a means of expanding their creative horizons. From printed leather bags that double as functional art to wood and metal wall art that transcends traditional canvases, this trend offers new avenues for creative expression.

5. Industrial and Manufacturing: Precision and Customization

The industrial and manufacturing sectors benefit from printing on unconventional surfaces for a variety of applications. Whether it’s labeling products, customizing components, or creating durable markings, printed surfaces play a vital role in precision and customization.

6. Construction and Infrastructure: Building the Future

In the realm of construction and infrastructure, 3D printing on unconventional surfaces has ushered in a new era of creativity and efficiency. Architectural designs that were once considered too complex or costly are now achievable through 3D printing technology. This technology has transformed construction, offering architects newfound freedom to bring their visionary designs to life.

Challenges and Considerations: Navigating the Unconventional

While printing on unconventional surfaces offers exciting possibilities, it comes with its own set of challenges and considerations that designers and manufacturers must navigate:

1. Surface Preparation: The Foundation of Quality

Different surfaces require specific preparation to ensure proper adhesion and print quality. Surface cleaning, priming, and treatment may be necessary to create the ideal canvas for printing. Surface preparation is a critical step that directly impacts the longevity and vibrancy of printed designs.

2.

Ink Compatibility: Choosing the Right Ink

Selecting the right type of ink is crucial for achieving durable and vibrant prints. Ink compatibility with the surface material is a critical consideration to ensure that the ink adheres properly and resists fading or wear over time. Matching the ink’s properties to the surface’s characteristics is essential for achieving optimal results.

3. Durability: Endurance in the Face of Challenges

Printed surfaces may be subjected to various environmental conditions, such as UV exposure, moisture, and physical wear. Ensuring the durability of printed designs is essential to maintain their visual appeal and functionality over the long term. Advanced UV-curable inks and coatings are often employed to enhance durability and resistance to external factors.

4. Cost and Expertise: Investment and Skill

Printing on unconventional surfaces often requires specialized equipment and expertise. The initial setup costs, including the purchase of printing technology and training of personnel, may be a barrier for some businesses. Moreover, the expertise required to handle various materials and achieve desired results adds to the complexity. Investing in the right equipment and skilled personnel is crucial for successful unconventional surface printing.

5. Design Considerations: Adapting to Unique Challenges

Designing for unconventional surfaces demands a keen understanding of the unique challenges and opportunities they present. Designers must consider factors such as texture, size, and surface curvature when creating artwork or layouts. The successful integration of design and technology is crucial for achieving stunning results. Collaborative efforts between designers and printers are often necessary to overcome the unique challenges posed by each unconventional surface.

A World of Creative Potential

Printing on unconventional surfaces has unlocked a world of creative potential, pushing the boundaries of design, communication, and innovation. From architectural marvels that redefine skylines to personalized fashion that reflects individual tastes, the ability to print on a diverse range of materials has transformed industries and inspired visionary thinking.

As technology continues to advance, we can expect even more exciting developments in the realm of unconventional surface printing. The convergence of design, technology, and craftsmanship has given rise to a new era of creative expression, where the only limit is the imagination.

Whether you’re an architect envisioning the future of building design, an interior designer seeking to transform spaces, or an artist exploring new mediums, the world of unconventional surface printing invites you to explore, create, and redefine the possibilities of design. It’s a journey into a realm where creativity knows no bounds, and innovation thrives on the canvas of the unconventional. Embrace the challenge, and explore the limitless potential of printing on unconventional surfaces. The world is your canvas, and with the right tools and imagination, you can leave an indelible mark on it. The future of design and printing is limited only by our creativity and willingness to push the boundaries of what’s possible. So, go ahead and embark on this exciting journey of creative exploration—it’s a world of endless possibilities.